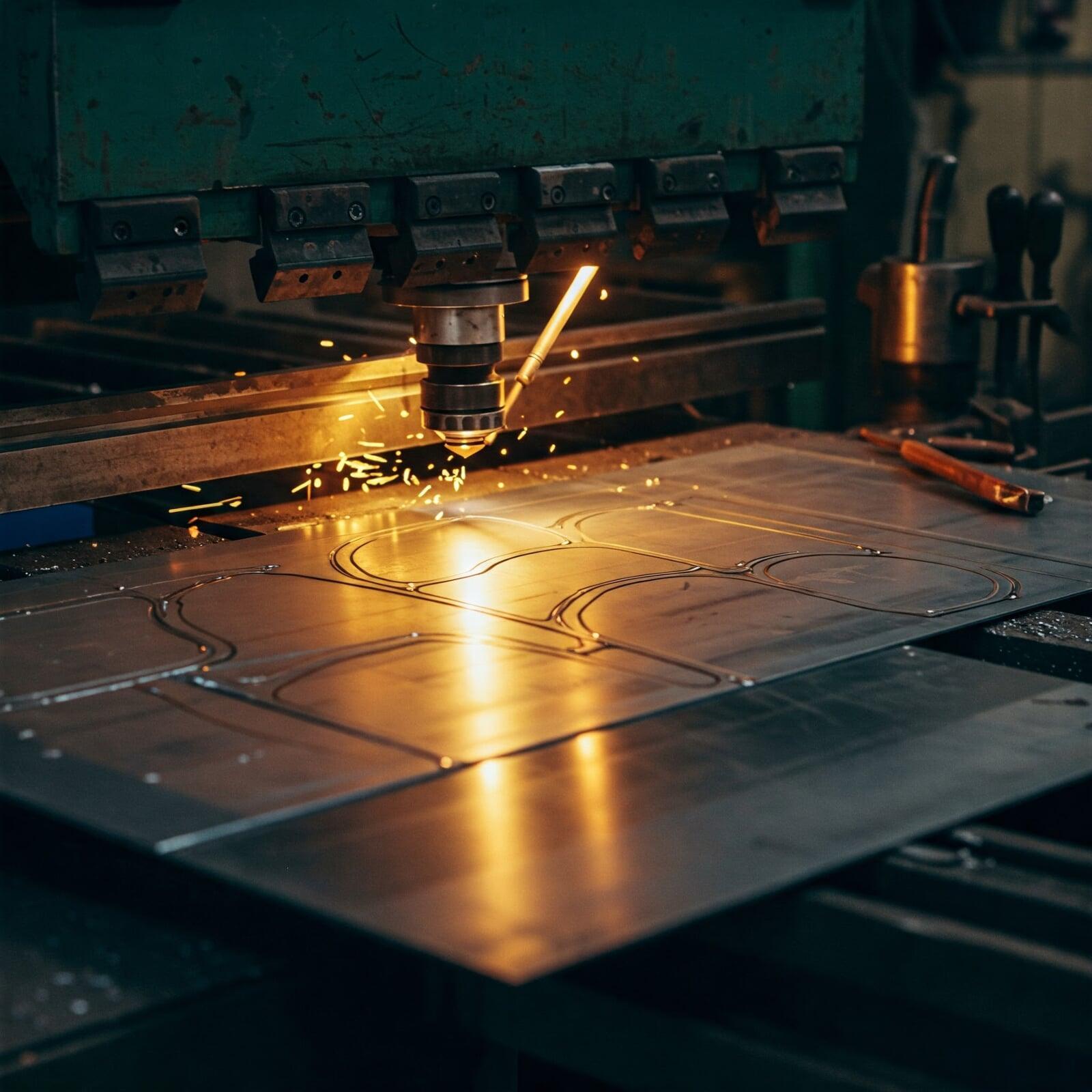

Trustbridge offers world-class sheet metal fabrication services through a global network of certified partners. Whether you're building early-stage prototypes or scaling to full production, our platform intelligently matches your project with suppliers that specialize in cutting, bending, forming, and welding sheet metal to your exact specifications.

With in-house engineering support and access to advanced equipment — from fiber lasers to CNC brakes and robotic welders — we ensure consistent quality, fast lead times, and turnkey production for parts that demand strength, precision, and scalability.

Why Choose Trustbridge?

1. Designed for Real-World Manufacturing (DFM-First Approach)

Most design firms operate like architects—we operate like builders.

We don’t just sketch ideas; we design products that are actually ready to be manufactured. Our team specializes in Design for Manufacturing (DFM), applying deep knowledge of materials, processes, tolerances, and cost drivers from the very beginning. The result? Designs that move seamlessly into production—faster, cheaper, and with fewer headaches.

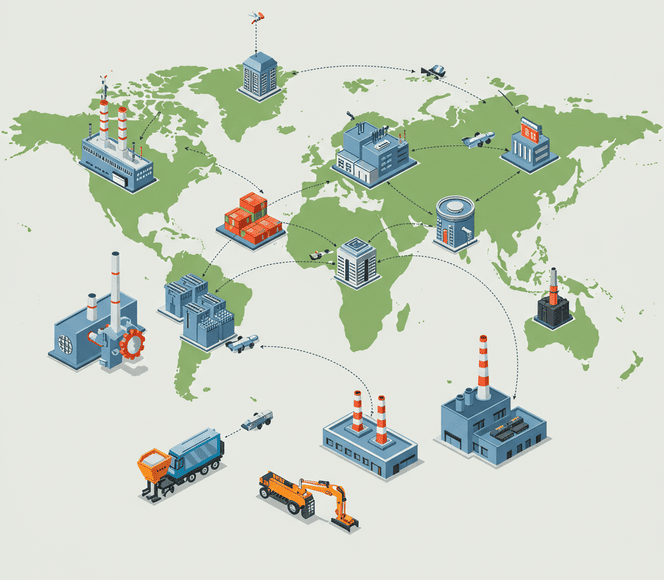

2. Built-In Access to a Global Manufacturing Network

Most design houses stop at the CAD file—we take you to the finish line.

Trustbridge is uniquely embedded within a global network of trusted manufacturing partners. Whether it’s CNC machining, injection molding, 3D printing, or casting, we know the vendors who can do the work—and we introduce you directly. No gatekeeping. No middlemen. No production black box

3. A Strategic Partner, Not Just a Design Vendor

We’re not order takers—we're problem solvers.

We collaborate with your team to optimize function, manufacturability, and cost from the outset. Whether you're an early-stage startup or an enterprise engineering team, our agile, expert-led design process keeps your project moving forward with speed and precision.